Shut-down over limit detection and peak detection

Insulation fault of the test object can be detected by several criteria. Insulation fault alarm will be triggered by a current over limit exceedance or by a special peak detection in order to detect even low-energy spikes.

Voltage ramp and detection of disruptive discharge voltage

The voltage ramp can be switched on in addition. Parameters like rise time and fall time are freely selectable. The voltage ramp enables safe testing and it is absolutely necessary for testing to norms which require special voltage curves. The voltage at which an isolation fault is detected, will be permanently displayed as a flashing value.

Key panel interlock

The key panel interlock prevents incorrect setting of parameters. It can be set up individually. For example all pushbuttons may be locked. Also desired functions can be left unlocked.

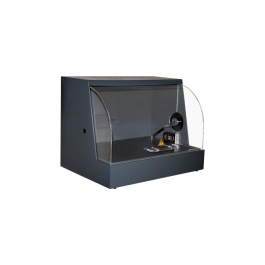

Test device for operating “Stand-Alone” or remotely controlled via interface

The test device can be controlled by a Windows software (user interface software DataView), by a self created custom software application (DLL, C#, .NET, LabView), simple command parameters (ASCII) or digitally with a PLC (Digital-IO).

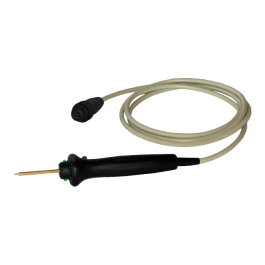

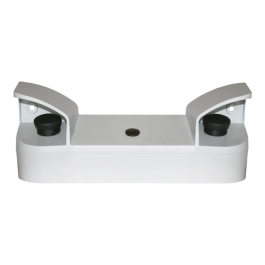

Automatic start up

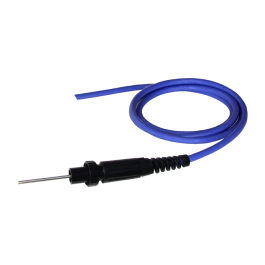

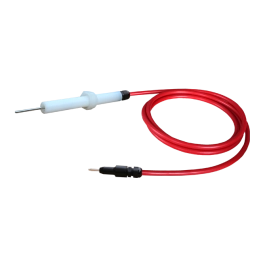

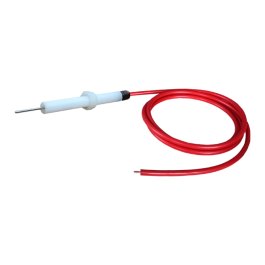

The start signal can be triggered by slightly pressing the test pistols to the test object. The test voltage will only be switched-on when the tips of both test pistols are safely connected to the test object. This will prevent the test object from voltage peaks and ensures the correct test time.

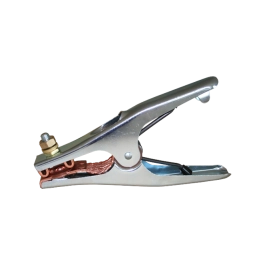

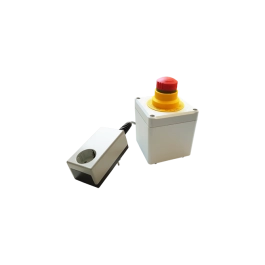

Cable break monitoring and connection monitoring to the test object

The high voltage cables are designed for 4-wire technology. Source-sense monitoring ensures maximum process reliability (patent).

Freely programmable sets of parameters

15 freely programmable sets of parameters are available for recalling test parameters.

Signalling: Acoustic, optical and communication interface

Faulty test objects can be reliably identified. Indication lights will also flash additionally.

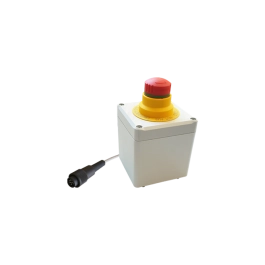

Safety circuit including two forcibly guided safety relays

The safety technology is designed according to EN 50191.

Measuring of current and voltage directly on the high voltage section

Direct measurement guarantees absolute accurate test results.

Regulated test voltage

Continously PI-controlled (power integral) test voltage is stabilized regardless of fluctuations in the mains voltage.

High voltage, potential-free

The test voltage is potential-free. This grants highest possible security for the operating person and this is a requirement for performing high voltage tests by using test pistols.

Individual setup

Start options, language, behaviour of digital IO interface, voltage ramp options, options for connection and cable break monitoring, etc.

Updatable via interface

For customer specific adaptions and updates.